Wastewater Visibility News

What types of structures does U.S. Submergent Technologies clean?

What types of structures does U.S. Submergent Technologies clean?

U.S. Submergent Technologies cleans sand, grit, and other debris out of wet environments. We’re well known for our success in wastewater treatment facilities, but our Combination3® technology gives us the ability to clean the hard-to-reach places in a variety of submerged conditions.

Our innovative jetter and combined vacuum and downhole system enables the rapid removal of accumulated solids from wet infrastructure while it remains in operation. U.S. Submergent Technologies (USST) is able to restore capacity in numerous industries and other systems that can benefit from being cleaned while in service, with no bypass.

Pipes

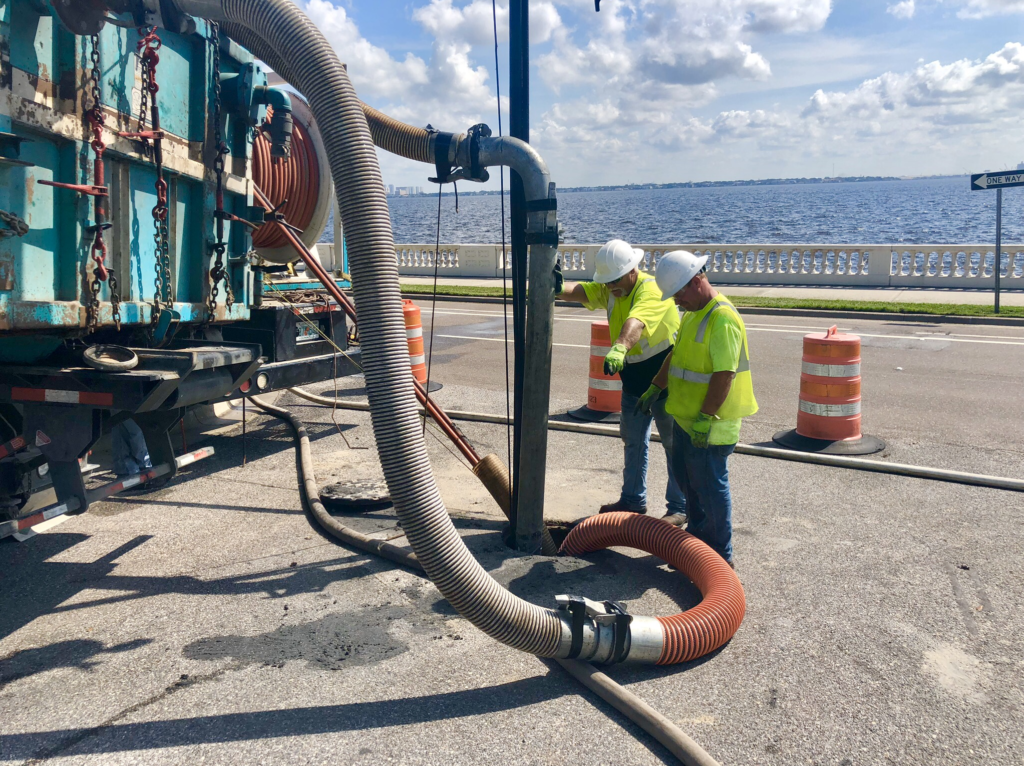

Large-diameter pipe systems can become clogged with sand or debris, causing blockage, reducing flow capacity, and causing potential upstream flooding. Over time, sand seeps into collection systems through cracks and seams, constricting pipe flow once it begins to accumulate.

Other unwanted debris, both naturally occurring and manmade (litter), makes its way into pipe systems, adding to the problem and obstructing flow. Other unwanted debris, both naturally occurring and manmade (litter), makes its way into pipe systems, adding to the problem and obstructing flow. Since we are unable to see the accumulated material, the problem often goes unnoticed. When this impacts a lift station, energy costs can rise significantly as well as wear and tear on equipment.

If capacity isn’t restored, a blocked pipe could potentially cause flooding and water damage in the surrounding areas, as well as impeding overall flow. USST removed 32-tons of sand from a stormwater pipe in Miami-Dade county under surcharged conditions. With USST’s technology, our crews can clear blockages in submerged or surcharged conditions without the need to bypass flow and without resorting to confined space entry.

Examples of pipe systems USST has the ability to clean appear below:

- Gravity/Sanitary Sewer Collection Pipes

- Outfall Pipes

- Siphons

- Stormwater Systems, including box culverts and baffle boxes

Tanks

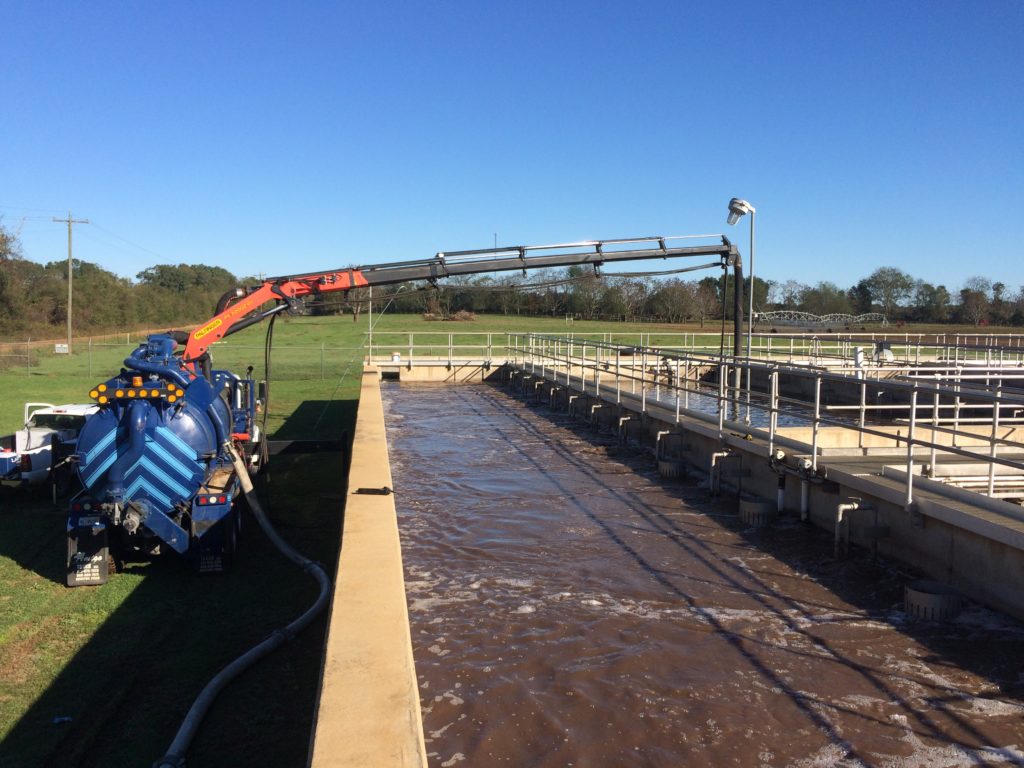

There are many types of tank structures used in a variety of ways in wastewater treatment systems, and they can all experience reduced capacity from the gradual accumulation of sand, grit, FOGs, rag material, vegetation, and more. Buildups of these types of material leads to increased energy costs and reduces overall plant efficiency.

With the assistance of USST’s patented equipment and process, our crews can tackle the toughest of issues, often while the system or structure remains in full operation in submerged conditions. We provide facilities the option to maintain a regular maintenance schedule instead of performing costly repairs or replacing expensive infrastructure.

USST can clean the following, but not limited to, structures:

- Aeration Basin

- Anoxic Tank

- Backwash Basin

- Clarifier

- Chlorine Contact Chamber

- Digester

- Effluent Channel

- Equalization Basin

- Grit Chamber

- Gypsum Pond

- Headworks

- Influent Channel

- Lagoon

- Methane Tank

- Oxidation Ditch

- Package Plant

- Ponds

- Reject Pond

- Sand Filter

- Sediment Trap

- Sludge Tank

- Splitter Box

- Storage Tank

- Surge Chamber

- Trickling Filter

Lift Stations

Lift or pump stations are an integral part of the wastewater collection system. They transport wastewater from lower to higher elevations and are often equipped with one to three pumps for redundancy. Lift stations tend to accumulate sand and grit due to unwanted inflow and infiltration (I&I) issues during periods of high flow (e.g., heavy rain or high tourist traffic) which can clog the system. The more sand in a wet well, the more frequently the pumps must start and stop due to reduced cycle times. A facility may only have one operating pump, putting undue stress on the already limited capacity of the structure.

Performing regular lift station maintenance reduces the risk of sanitary sewer overflow (SSO), where untreated wastewater is discharged from a sewer into the environment before reaching a wastewater treatment facility. SSO can have extremely negative consequences for the environment and population in the areas surrounding the overflowing wet well.

With USST’s Combination3® truck and patented GritGone Process®, our crews can clean lift stations with one piece of equipment and quickly switch between cleaning modes to solve most access issues. The jetter has the ability to clean the structure, and the vacuum removes material such as fats, oils and greases. The truck’s downhole pump removes sand and grit from the wet well while the lift or pump station remains in full operation at full capacity, without the need for confined space entry.

- Lift or Pump Stations

- Wet Wells

Author Notes

Wastewater Visibility News

Tags:

More Recent Posts

First-Ever National Drinking Water Standard to Protect 100M People from PFAS Pollution

Are Your Wastewater Tanks Consuming Excess Energy Due to Sand and Grit? Emerging Technology Can Help You Find Out

Happy Easter

Efficiency in Serving Wastewater Utilities

Subscribe

Get news delivered straight to your inbox the day it gets published."*" indicates required fields