Wastewater Visibility News

Why is grit buildup a problem for wastewater treatment facilities?

Why is grit buildup a problem for wastewater treatment facilities?

Our wastewater collection and treatment systems remove the biological waste in our water by design. However, other waste — debris such as sand and grit — accumulates in collection and treatment infrastructure, but their systems are not designed to remove this type of material. This type of debris accumulates because most of the wastewater infrastructure is below the earth’s surface. Collection systems are comprised of pipe segments that have joints, seams, gaps, and cracks, which are exacerbated as the pipes shift over time. These gaps allow sand to enter the pipe.

The Damage Done by Grit

Sand and grit, unmanaged, can wreak havoc on the treatment process by reducing the operating capacity of the system. Sand and grit cause abnormal wear and tear on pumps and other mechanical components. Hydraulically speaking, sand and grit can adversely affect operational aspects of the collection and treatment system including full or partial plugging of outlets and/or pump suctions.

The Risks of Grit and Sand Accumulation

Determining whether or not there is an issue is the real challenge. Pipes are below ground while tanks are made of concrete or steel and are not transparent. Accumulated sand and grit sits at the bottom of these structures, reducing valuable capacity, until issues such as overflows make it clear that immediate attention is needed.

Equipment failure is a problem for wastewater facilities because it often takes a significant amount of time to repair or replace the equipment in question, resulting in the system running at reduced capacity or having to figure out a bypass solution. In smaller facilities, there may not be an option to divert or bypass flow, leaving them in a critical situation that requires a quick resolution.

A Solution to Unwanted Grit and Sand

Often, the first solution to restoring critical capacity is to build new infrastructure. This option is costly, and municipalities must spend a great deal of time to navigate a lengthy approval process, financing, design, and finally, constructing new infrastructure.

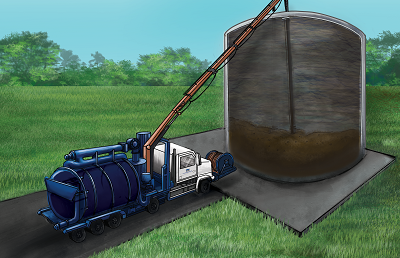

Instead, facilities can save money and ensure optimum capacity by scheduling regular maintenance to manage sand and grit accumulation. U.S. Submergent Technologies’ Combination3® Truck and GritGone Process® make it possible to remove grit from pipes, tanks and lift stations without shutting down the facility or requiring bypass pumping. USST can also remove material in submerged or surcharged conditions and reduce or eliminate the need for confined space entry.

Removal of material can reduce energy demands and allow structures to return to their design capacity. Regular maintenance to remove accumulated grit is a much less costly solution than rebuilding infrastructure or replacing entire pipe systems.

Call a USST Project Advisor to learn more about how we remove material from hard-to-reach environments. Talk to us at (844) 958-1207 or email us at info@ussubmergent.com.

Author Notes

Wastewater Visibility News

Tags:

More Recent Posts

First-Ever National Drinking Water Standard to Protect 100M People from PFAS Pollution

Are Your Wastewater Tanks Consuming Excess Energy Due to Sand and Grit? Emerging Technology Can Help You Find Out

Happy Easter

Efficiency in Serving Wastewater Utilities

Subscribe

Get news delivered straight to your inbox the day it gets published."*" indicates required fields