Wastewater Visibility News

Case Study at a Southwest Florida Wastewater Treatment Plant

Summary of a case study on the use of informed data at a five million gallon per day (5 MGD) Southwest Florida wastewater treatment plant.

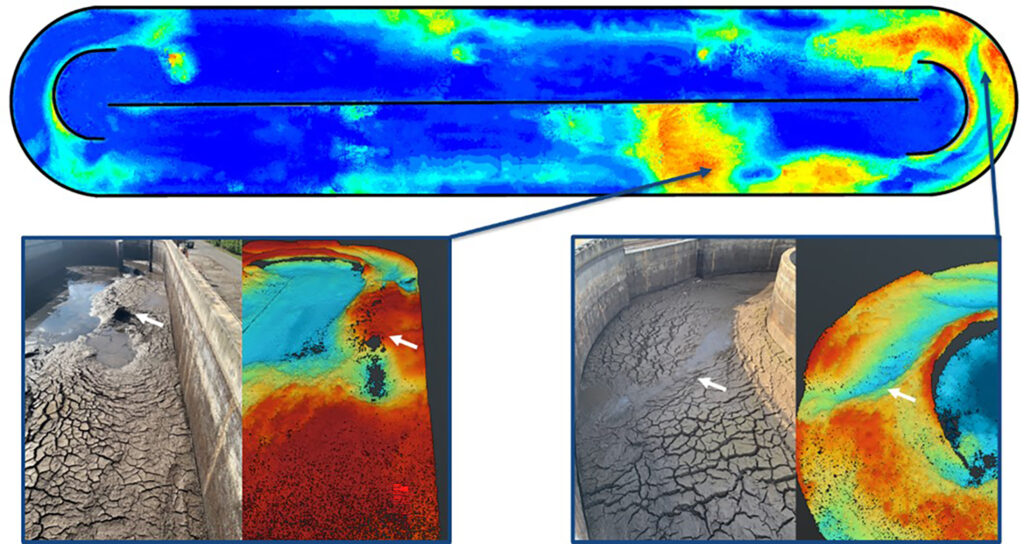

In 2018, Denver J. Stutler, Jr., P.E., began collaboratively developing SediVision® to deliver transformational technology in the wastewater industry. The objective of SediVision is to provide reliable, accurate informed data to utilities and wastewater operators regarding the scope and location of debris in wastewater tanks.

Historically, the inability to see within dark water has forced wastewater managers and utilities to operate speculatively with regard to when their wastewater tanks truly required cleaning. “Left in the dark,” decision-makers relied on physically probing tanks for indicators of debris density and volume, hiring divers to attempt assessments, or creating projections based on previous patterns.

The technology developed by SediVision maps accessible tank areas to provide reliable and accurate information about the contents of tanks. As a result, facility operators can confidently plan and schedule maintenance.

The following information is a case study summary of the use of SediVision technology at a 5 MGD Southwest Florida wastewater treatment plant.

5 MGD Southwest Florida Wastewater Treatment Plant

Project: Two identical oxidation ditches measuring 80 feet by 440 feet are part of a utility in southwest Florida.

History and Status: The east oxidation ditch was fully drained and then cleaned in recent years. At the time of the cleaning, the utility operators had no way of knowing the amount of material that would need to be removed.

In 2022, the facility prepared to clean and drain the west oxidation ditch. With its operations budget already strained by previous hurricanes, the utility operator made a strategic decision to obtain informative data via a SediVision assessment prior to scheduling the cleaning.

Findings: The SediVision assessment identified the location and estimated volume of over 1700 CU Yds of sediment. The assessment validated the timing and expenditure for cleaning the tank, which was functioning at a 12 percent capacity loss, against the industry-identified threshold of 10 percent capacity loss as the standard for “Needs Maintenance.”

Action: The project advanced thanks to the availability of credible information (provided by SediVision mapping) regarding the nature and location of the sediment in the west oxidation ditch. The utilities operator knew with confidence that the cleaning was not only advisable but was wholly necessary.

Results: The sediment’s topography aligned with the assessment provided by SediVision. The job was completed with no unanticipated findings. The cleaning contractor found the SediVision data helpful for forecasting job duration and the resources required to finish the project.

Unique Project Variable:

Following the SediVision assessment and prior to the cleaning, the utility was impacted by Hurricane Ian on September 23, 2022. Although not verified, it is reasonable to assume that the hurricane increased debris within the system. Some water was present in the debris transported offsite, as the material in situ could not be fully dewatered through the cleaning operation. Despite this variable, the pre-hurricane assessment of the amount of material was within 16 percent of the actual amount removed.

Learn more about the ways wastewater utilities are strategically using Sedivision technology as a predictive maintenance tool. SediVision for the Wastewater Industry

Request information or request a no-obligation proposal for your wastewater facility.

Author Notes

Wastewater Visibility News

More Recent Posts

105.668 Gallons of Wastewater to be Reused Daily in the Manufacture of Semiconductors

First-Ever National Drinking Water Standard to Protect 100M People from PFAS Pollution

Are Your Wastewater Tanks Consuming Excess Energy Due to Sand and Grit? Emerging Technology Can Help You Find Out

Happy Easter

Subscribe

Get news delivered straight to your inbox the day it gets published."*" indicates required fields