Wastewater Visibility News

Are Your Wastewater Tanks Consuming Excess Energy Due to Sand and Grit? Emerging Technology Can Help You Find Out

SediVision is pleased to share an in-depth article on the impact of sand and grit on the energy consumption of wastewater tanks. The article was published in the March 2024 issue of the Florida Water Resources Journal and is published here with the magazine’s permission.

Wastewater treatment facilities face significant challenges in maintaining operational efficiency and cost-effectiveness, particularly when dealing with grit accumulation within tanks. Grit accumulation in biological nutrient removal (BNR) tanks creates lost treatment capacity for wastewater facilities, which can inhibit operational performance. Many utilities lack an effective tank cleaning maintenance program, resulting in higher energy demands, particularly when grit accumulates on diffusers in aeration tanks. Although a grit removal system may be in place, no system is 100 percent effective, and utilities often bypass systems during wet weather events and storms as a result of hydraulic limitations. Typical strategies for assessing the amount of grit have included probes, divers, and drain downs. All these strategies have challenges, including significant inaccuracies and safety risks.

This issue is compounded by the projected growth expectations in the water sector, where energy demands are projected to double by 2040. Currently, the water sector accounts for almost 44 percent of municipal energy demands, making it an extremely energy-intensive process. It’s important to focus on strategies that not only build new energy-efficient facilities, but develop enhanced optimization programs that can reduce the current excessive consumption of energy.

Aeration accounts for anywhere between 30 and 70 percent of the total energy demands within a wastewater treatment facility, making it a primary focus of optimization to achieve a lower carbon footprint. Grit accumulation in aeration basins is a common problem and can drive up energy demands due to clogging and blocking diffusers, or reduced detention time for treatment, necessitating blowers to work harder to achieve optimal dissolved oxygen demands. Simply implementing a proactive method to identify areas of grit buildup and incorporating strategies for cleaning can greatly reduce a wastewater treatment plant’s carbon footprint without any capital investment. Conversely, not all systems have a grit accumulation problem and therefore can defer both operating and possibly capital expenditures by evaluating the level and impact of grit deposition in treatment tanks.

Tank Cleaning Challenges

Many utilities do not know how much grit has accumulated in their wastewater tanks or where it’s located, and they can’t drain their tanks due to limited redundancies and capacity issues from wet weather. Developing a tank cleaning strategy, therefore, is difficult because quantities and locations of accumulated grit and debris are challenging to estimate.

Traditional methods, such as probing, can be extremely unreliable for several reasons, including lack of access to all portions of the tank. Grit particles in wastewater do not accumulate uniformly across the tank and typically accumulate in piles based on the velocity profile within the tank. Inaccurate grit profiling can lead to either unnecessary tank drain downs or costly change orders. Divers have also been used to assess grit accumulation; however, the level of accuracy of divers is not well-documented and using divers poses a significant safety risk with confined space entry.

Inflow analysis is used to estimate the average amount of grit in the influent of a wastewater plant or to measure the performance of a grit removal system, but this analysis will not evaluate the deposition of grit within the treatment tanks, and thus still leaves a gap in the ability to assess current conditions within the treatment facility.

Tank Cleaning Costs

The difference of 1 ft of grit can mean well over $100,000 in cleaning costs. This creates risk and uncertainty for utility owners and operators, as well as consultants and contractors attempting to bid on wastewater projects that include tank cleaning as a bid item. Table 1 outlines estimated cleaning costs for a 1,250-sq-ft tank versus a 20,000-sq-ft tank; however, restoring wastewater treatment capacity is still much more cost effective than building new capacity.

Using Advanced Imaging and Mapping Technology

An emerging technology called SediVision was developed in 2018 and has since been deployed to over 150 tanks at more than 85 wastewater treatment facilities in Florida and other states. The technology is an advanced imaging and mapping system that can provide a valuable solution to determine loss of capacity within wastewater tanks. By using this tool, utilities can easily see where grit accumulation may be inhibiting performance, thus empowering facility managers to make data driven decisions, effectively optimizing their asset management strategies and reducing cost uncertainty.

Case Studies

Lee County Water Reclamation Facility

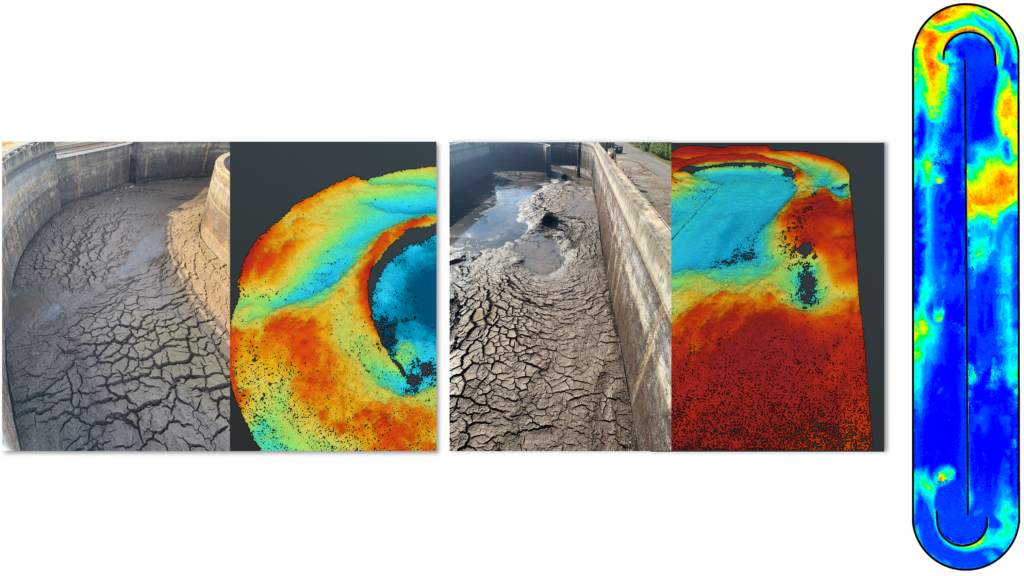

Figure 1. Lee County (FL): SediVision helped justify and develop cleaning budget; results accurate within 1% of actual grit removed

One of the early breakthrough case studies using this technology was in Lee County at the Fiesta Village Wastewater Treatment Plant, a 5-mil-gal-per-day (mgd) facility. The county utilized this advanced technique to scan its oxidation ditch, revealing a substantial 1,769.3 cu yds of grit accumulation, resulting in 11.9 percent of lost treatment capacity. These findings were pivotal in justifying and developing a precise budget for cleaning and maintenance. Figure 1 shows the imagery and mapping collected on the full tanks compared to the drained down image, pointing out the accuracy of key indentations of the accumulated grit.

This study was instrumental in calibrating the quantification techniques of this technology. Through verifying disposal weight tickets of the debris, data processing calculations were able to be modified to estimate the weight of the material to an accuracy within 1 percent.

Clewiston Water Reclamation Facility

A small rural facility in Clewiston, with a capacity of 1.5 mgd, realized tangible financial benefits from adopting this innovative technology. Prior to the assessment and tank cleaning, the facility was running aeration blowers 24 hours a day. After removing 400 tons of sand and grit from the tanks, it only required aeration blowers to run eight hours a day. The result yielded remarkable monthly energy cost savings, ranging from $1,000 to $2,000 as a direct result of effective tank cleaning and management. Figure 2 shows a graph comparing energy costs pre- and post cleaning.

JEA Blacks Ford Water Reclamation Facility

Ardurra was hired by JEA to expand the Blacks Ford Water Reclamation Facility in St. Johns County from 6 to 12 mgd. The project included an evaluation of multiple tanks totaling 56,000 sq ft of surface area to determine if a grit removal system should be implemented as part of the expansion. The current facility does not have a grit removal system and Ardurra was interested to find out how much grit had accumulated in the existing BNR trains.

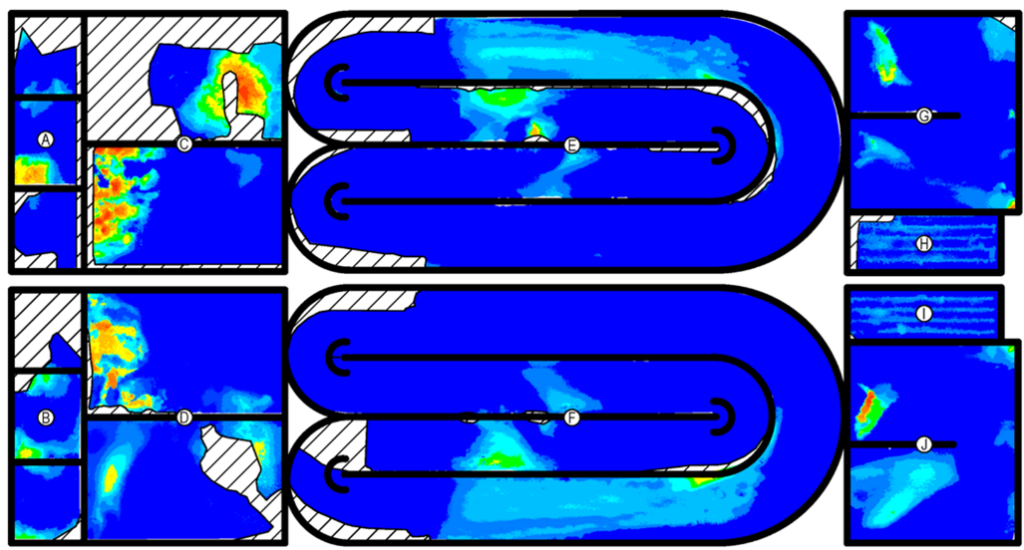

Figure 3. JEA Water Reclamation Facility (FL): SediVision technology justified $6-8M deferred capital cost for Grit Removal Facility

By analyzing the grit accumulation using advanced imaging and mapping technology, Ardurra was able to assess that the entire system had an in-tank grit accumulation volume estimate of 815 cu yds. This was calculated to be approximately 2.4 percent of overall lost treatment capacity, which justified the decision to not install a grit removal system as part of the project. This resulted in an estimated capital cost savings of anywhere from $6 million to $8 million and saved space on a constrained site.

Pinellas County South Cross Bayou Advanced Water Reclamation Facility

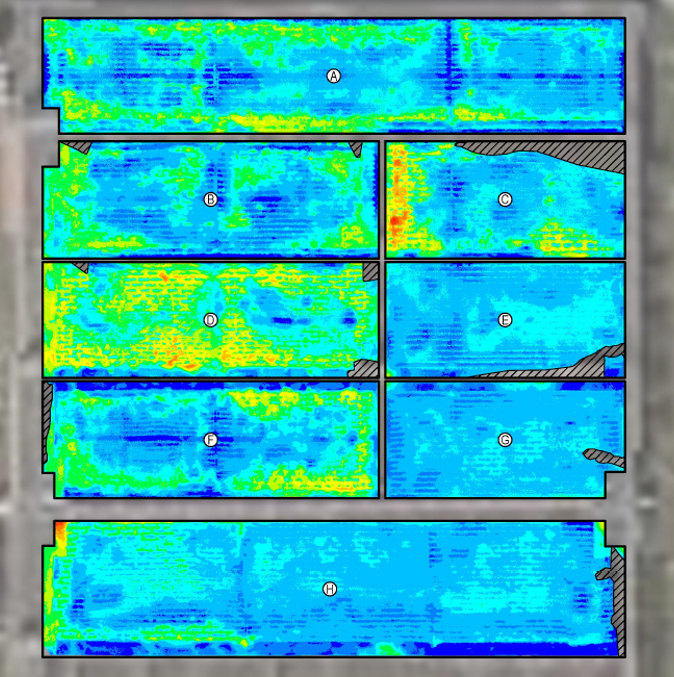

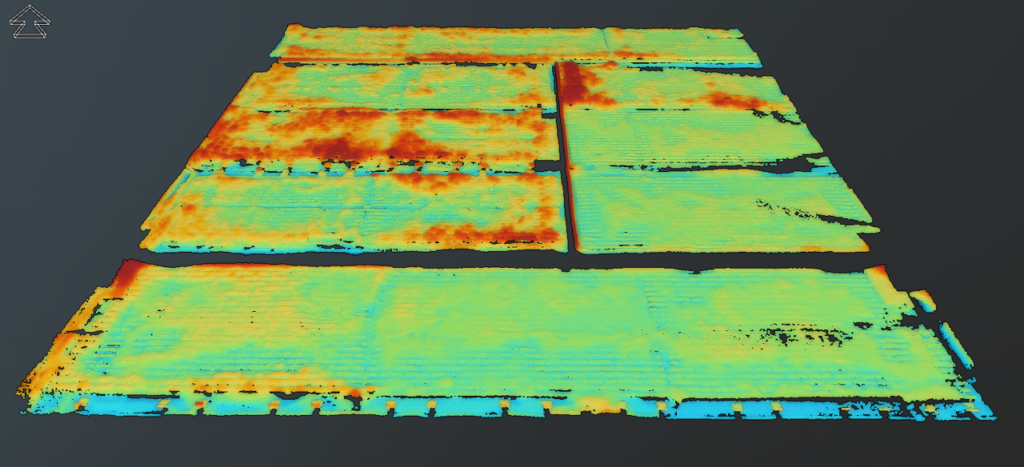

Figure 4. Pinellas County (FL): SediVision used at 33mgd Advanced Water Reclamation Facility to prioritize cleaning /develop multi-year budget. Results also used in process improvement for biological nutrient removal

The South Cross Bayou Advanced Water Reclamation Facility, a 33-mgd facility in Pinellas County, took the proactive step of scanning all of its aeration basins in the north train of the system. In addition to the tanks not being cleaned in several years, the facility had also recently undergone a capital project that completely upgraded and replaced the old grit removal system. As part of the construction, this required a prolonged bypass of the old system. In addition, prior to the upgrade, the old system was found to only have 50 percent removal efficiency at normal conditions and was also hydraulically limited, which necessitated a complete bypass during intense wet weather events.

Using the advancing imaging and mapping technology, the resulting assessment of multiple tanks totaling 70,000 sq ft of surface area identified accumulation that was likely responsible for excessive energy consumption, and the data served as a method to prioritize and budget for necessary tank cleaning, starting with tanks containing the most accumulated grit. Results indicated a total amount of 3,685.4 cu yds of accumulated debris, resulting in a total lost treatment capacity of 10.2 percent. Figures 4 and 5 depict the mapping images of the aeration basins.

Louisville Metropolitan Sewer District Cedar Creek Water Quality Treatment Center

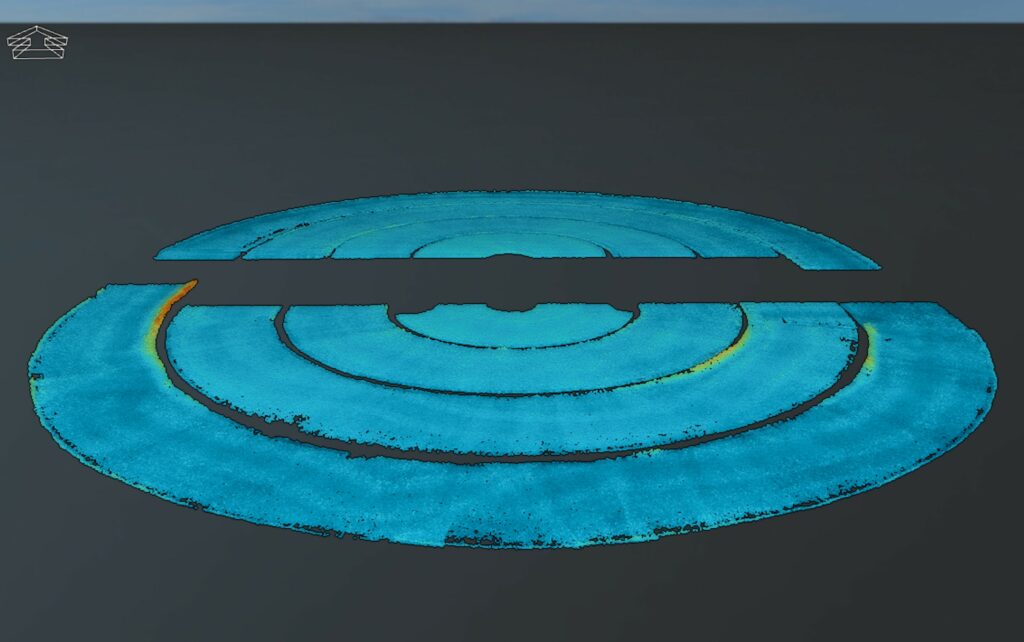

Figure 6. Louisville MSD (KY): SediVision technology enabled concentric channel oxidation ditch cleaning deferral and reallocation of funds.

The Cedar Creek Water Quality Treatment Center at the Louisville Metropolitan Sewer District is a 7.5-mgd facility. The treatment facility’s concentric channel oxidation ditch had not been cleaned in over 10 years. The use of advanced imaging and mapping of the tank revealed that it contained 73.9 cu yds, with a 0.6 percent loss of treatment capacity overall. This was deemed negligible and cleaning the tank was not recommended. The facility was able to reallocate the tank-cleaning funds to other higher-priority operational needs. Figure 6 depicts the 3-D imagery of the tank.

Conclusion

Implementing an improved methodology for assessing lost capacity in wastewater tanks can provide an effective and practical solution for wastewater tank asset management. The featured case studies illustrate how this approach can lead to improved operational efficiency, cost savings, reduced carbon footprint, and the sustainable functionality of wastewater facilities.

It should be noted there is a lack of research surrounding the impacts of grit and debris accumulation on wastewater facility operational performance, including impacts on energy efficiency. More research should be done to expand the body of knowledge within the wastewater sector so that this issue can be evaluated and addressed by utility managers.

With energy and chemical costs increasing dramatically for utilities over the past several years, every opportunity to identify operational efficiencies in wastewater plant performance should be evaluated and implemented where possible.

Thank you again to the Florida Water Resources Journal.

References

- Cardoso, B.J., Gaspar, A.R, Gomez, A., Rodrigues, E. 2021 “Energy Performance Factors in Wastewater Treatment Plants: A Review.” Journal of Cleaner Production. 322, 129107. Retrieved from https://doi.org/10.1016/j.jclepro.2021.12910

- EPA, 2003, Wastewater Technology Fact Sheet: Screening and Grit Removal. EPA 832- F-03-011, Office of Water.

- WEF 2017 Liquid Stream Fundamentals: Grit Removal. Fact Sheet WSEC-2017-FS-021— Municipal Resource Recovery Design Committee.

Additional published case studies.

Author Notes

Megan Ross, PE, ENV SP, Vice President, SediVision, LLC

Tags:

More Recent Posts

Subscribe

Get news delivered straight to your inbox the day it gets published."*" indicates required fields